Recipe data management involves organizing, storing, and handling information related to recipes, formulas, and ingredients used in food, beverage, or manufacturing industries. It encompasses everything from creating and documenting recipes to managing variations, tracking ingredients, ensuring compliance with safety standards, and maintaining quality control throughout production.

The importance of recipe management lies in several areas

Consistency: Ensuring products’ consistent quality and taste across batches and production runs.

Compliance: Meeting regulatory requirements and adhering to safety and quality standards set by governing bodies.

Efficiency: Streamlining the production process, minimizing errors, and reducing waste.

Traceability: Tracking ingredients and components used in recipes from their source through production to the end product.

Key challenges and risks in recipe management

Inaccurate Documentation: Errors in recording ingredients, measurements, or processes can lead to inconsistent products or non-compliance.

Lack of Standardization: Different units of measurement, naming conventions, or processes across teams can cause confusion and errors.

Compliance Issues: Failing to meet safety or regulatory standards, leading to potential legal or reputational risks.

Limited Traceability: Difficulty in tracking ingredients and their sources can hinder recall efforts or quality control.

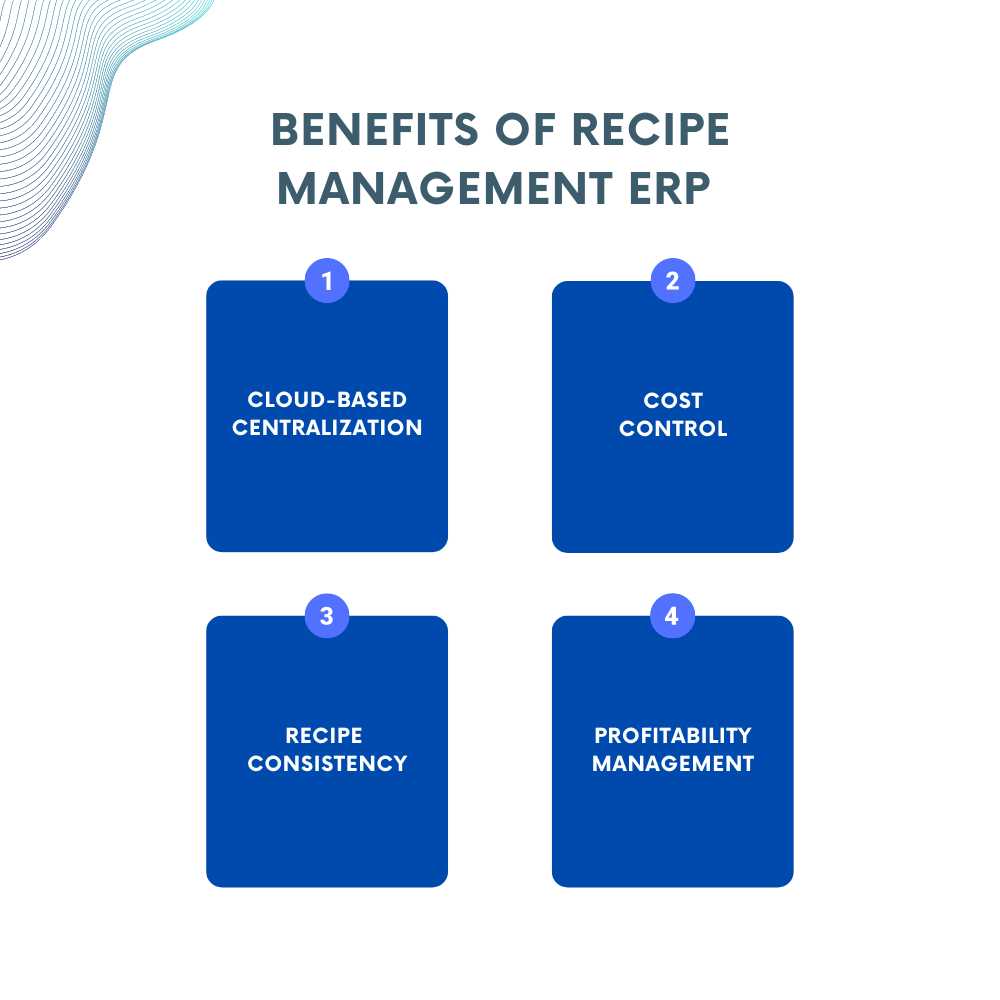

Benefits of managing formulas and recipes with ERP software

Improved recipe management: Centralized storage and standardized formats for recipes and formulas.

Maintaining safety standards: Ensuring adherence to safety regulations and guidelines.

Improving compliance: Meeting regulatory requirements and quality standards.

Ensuring traceability: Tracking ingredients and components throughout the supply chain.

Enhanced quality management: Consistent quality control measures and easier identification of issues.

Greater stock and cost control: Optimizing inventory and production costs.

Improving packaging: Enhancing product presentation and compliance with packaging standards.

Manage consumer expectations: Ensuring consistency and meeting consumer demands for quality and safety.

Recipe management systems find applications beyond the obvious culinary realm in various industries. While they are indispensable in restaurants, catering services, and food manufacturing, their utility extends to pharmaceuticals for precise medication creation, where formulas act as recipes.

They’re also vital in cosmetics for blending precise formulations, manufacturing for consistent production of chemicals, and even in agriculture for creating optimal crop treatments.

Moreover, recipe management systems are increasingly sought after in healthcare for dietary planning and nutrition management, showcasing their diverse utilization across multiple sectors.

Recipe Management in Beverage Manufacturing

Recipe management in beverage manufacturing businesses involves meticulously orchestrating ingredients, proportions, and processes to craft the perfect concoction. It’s a blend of science and artistry, where precision is paramount. Each recipe is a closely guarded secret, meticulously documented and safeguarded, as it forms the soul of a brand.

The process demands rigorous attention, from sourcing the finest ingredients to calibrating the exact measurements. Technology plays a pivotal role, with advanced software aiding formulation, tracking, and ensuring consistency across batches. In this intricate dance of flavors, recipe management stands as the cornerstone, shaping the distinctive identity of every sip.

Recipe and formula Management in the pharma Manufacturing industry

Recipe and formula management within pharmaceutical Manufacturing is the bedrock of producing life-changing medications. It involves an intricate balance of precise formulations, stringent regulations, and cutting-edge technology.

Every pharmaceutical product begins as a meticulously crafted recipe, incorporating precise measurements of active pharmaceutical ingredients, excipients, and manufacturing processes. These formulas are guarded with the utmost confidentiality and managed with specialized software systems that ensure accuracy, compliance, and traceability throughout the production cycle.

The integrity of these formulas directly impacts the quality, efficacy, and safety of the medications that ultimately reach patients, highlighting the critical role of recipe and formula management in pharmaceutical Manufacturing.

Conclusion:

Acumatica ERP offers a comprehensive solution that can significantly enhance businesses’ recipe processes. Its robust features enable efficient recipe creation, management, and version control.

With real-time visibility into inventory levels, cost analysis, and production schedules, Acumatica empowers businesses to optimize ingredient procurement, streamline production workflows, and ensure compliance with industry regulations. Its integration capabilities with other systems and scalable nature make it an invaluable tool for improving accuracy, agility, and profitability within recipe processes.

Vijay comes with a vast experience in ERP and enterprise solutions space with about 20 years of experience in various packaged application like Acumatica, SAP, Orion, Salesforce.com, SugarCRM and, SalesLogix.