Precise demand forecasting is the cornerstone of effective business operations. It enables companies to efficiently manage inventory, align production schedules with market demand, and optimize resource allocation. However, many organizations struggle with demand forecasting, leading to costly inefficiencies and missed opportunities. Here are some common pitfalls in demand forecasting and how to avoid them.

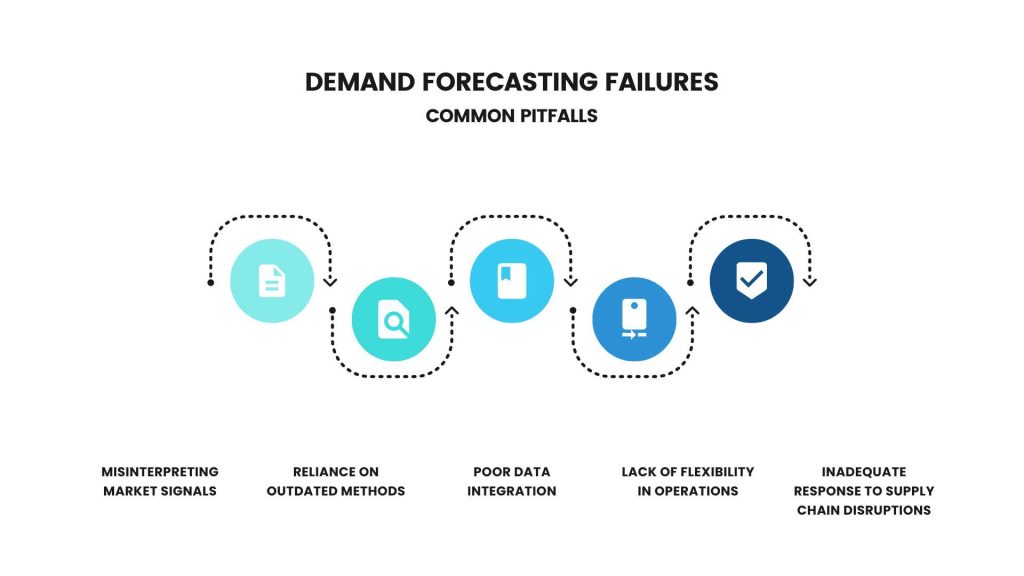

Demand Forecasting Failures

Lack of Flexibility in Operations

In today’s dynamic market, rigidity can be a significant downfall. Many companies fail to build flexibility into their operations, making it difficult to respond to sudden changes in demand.

Flexibility allows for rapid adjustments in production schedules, inventory levels, and resource allocation, which is essential for adapting to market fluctuations. Businesses should invest in agile systems that can fast pivot in response to new data.

Poor Data Integration

Proper demand forecasting relies heavily on the quality and integration of data from various sources. When data is siloed or poorly integrated, it can lead to inaccurate forecasts and misguided business decisions.

Companies must ensure seamless data integration across all departments. Implementing robust ERP systems that centralize and harmonize data can significantly improve forecasting accuracy.

Reliance on Outdated Methods

Many businesses still rely on outdated forecasting methods that do not account for modern complexities. Traditional methods may not incorporate real-time data, advanced analytics, or machine learning algorithms, leading to less accurate predictions.

Companies should adopt contemporary forecasting techniques that leverage the latest technology, such as AI and big data analytics, to enhance their predictive capabilities.

Inadequate Response to Supply Chain Disruptions

Supply chain disruptions are inevitable due to natural disasters, geopolitical events, or other unforeseen circumstances. Companies that do not have robust contingency plans and adaptive forecasting models are often caught off guard by these disruptions.

Businesses should develop flexible supply chain strategies and incorporate scenario planning into their forecasting processes, allowing them to quickly adjust to disruptions.

Misinterpreting Market Signals

Misinterpreting market signals can lead to inaccurate demand forecasts and inventory imbalances. Companies must be adept at distinguishing between short-term fluctuations and long-term trends.

It needs a deep knowledge of market dynamics and the ability to examine different indicators effectively. Utilizing advanced analytical tools and maintaining close communication with market stakeholders can help accurately interpret market signals.

Failure to Scale Forecasting with Business Growth

As businesses grow, their demand forecasting needs become more complex. Failure to scale forecasting processes and tools aligned with business growth can lead to inefficiencies and missed opportunities.

Companies must ensure their forecasting models and systems can handle increased volume and complexity. This may involve upgrading to more sophisticated ERP systems and continuously refining forecasting methodologies.

ERP Capabilities are Essential for Demand Forecasting

Real-time Reporting

Real-time reporting is crucial for accurate demand forecasting. It provides up-to-date information on sales, inventory levels, and market situations, allowing companies to make informed decisions quickly.

ERP systems with robust real-time reporting capabilities can help companies stay ahead of demand changes and adjust their strategies promptly.

Collaboration Tools

Effective demand forecasting requires collaboration across various departments, including sales, marketing, production, and supply chain. ERP systems with integrated collaboration tools facilitate seamless communication and data sharing, ensuring all stakeholders can access the same information and work together effectively to create accurate forecasts.

Advanced Analytical Capabilities

Cutting-edge analytical capabilities (predictive analytics) and machine learning are crucial for modern demand forecasting. This tool can interpret large amounts of data to find patterns and trends, delivering more accurate and actionable forecasts. ERP systems with built-in advanced analytics enable companies to leverage these capabilities without needing separate, standalone solutions.

Comprehensive Data Management

Comprehensive data management is the foundation of accurate demand forecasting. ERP systems must be capable of handling vast amounts of data from various sources, ensuring it is clean, consistent, and readily accessible.

Effective data management practices within ERP systems ensure businesses have a reliable basis for their forecasting models and can confidently make data-driven decisions.

Conclusion

By seamlessly integrating key functionalities such as resource management, demand forecasting, and real-time data analytics, Acumatica empowers manufacturers to elevate their production planning strategies to new heights.

With its robust capabilities, Acumatica helps businesses avoid common forecasting pitfalls and achieve greater operational efficiency and responsiveness to market demands.

Vijay comes with a vast experience in ERP and enterprise solutions space with about 20 years of experience in various packaged application like Acumatica, SAP, Orion, Salesforce.com, SugarCRM and, SalesLogix.