Businesses that have cloud-based ERP implemented in their system didn’t have to face much disruption. Everything that they need to work on was on the cloud, quickly and easily accessible. COVID has not only left a grievous impact on the health of the world population but has also shaken the global economy to the core. One of the industries to have been worst hit by the pandemic is the manufacturing businesses.

Nations leading in manufacturing had to suffer due to the traveling restrictions, shortages of labor, and other logistics challenges. The social distancing and quarantine have led to a shortage in labor. Procurement of raw materials, their supply became further challenging with the traveling restrictions. This has thus massively affected supply chain management.

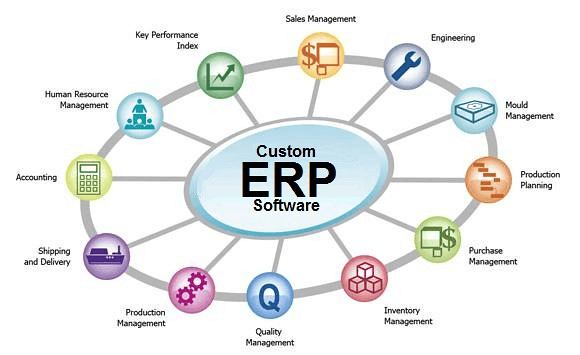

In today’s blog-post we are going to list down five ways with which ERP has helped manufacturers smoothly and efficiently run the business post-COVID.

Reinventing workplace with ERP

Of all the businesses, manufacturing was the first which was expected to succumb to the imposed social distancing and remote working norms. After all, manufacturing demands a workforce to be onsite for the product, quality control, and management. But alas, it has to comply. Businesses that did not have a cloud-based ERP like Acumatica had to deal with the horror of setbacks and managing everything on a spreadsheet. But with Acumatica, such is not the case. It gives the employees the freedom to work flexibly from any corner of the world, for as long as they have an internet connection. It, not just the work that they can perform remotely, they can communicate across departments with ease. ERP can also forecast problems in the process early on and only requires a remote operation to fix them. Thus, Acumatica has reduced the need for onsite personnel, and improved operational efficiency.

Traceability is being reconsidered

Traceability is the feature that allows tracking the product right from its inception to its delivery so that there is no issue of a compliance breach. This also helps in quickly recalling the batches in case faulty products have been supplied or have reached the market. With cloud-based ERP like Acumatica, you will be able to leverage traceability. With COVID, the focus on the quality of the products has especially heightened. An increasing number of manufacturing businesses are going digital because of the inability to conduct third part auditing and verification. Cloud-based ERP like Acumatica in today’s situation will help keep traceability in control.

The supply chain has become flexible

Did you know that manufacturer’s spending on ERP might increase to $14bn by 2024, as predicted by research by ABI? The reason lies in its ability to make the supply chain flexible by leveraging the data and changing shopping patterns of the consumers from the cloud facility. Managing supply chains has become easy with ERP. It provides real-time visibility that proves instrumental in making informed decisions regarding demand and supply forecasting. Furthermore, since ERP minimizes reliance on manual labor, supply chain efficiency gradually boosts with unerring accuracy.

So here we conclude with three of the many ways manufacturing businesses performance has exponentially increased because of ERP. If you haven’t implemented it yet, there is no time better than now. Reach out to Tayana Solution for Acumatica. A leading cloud-based ERP implementation that helps businesses, small to medium scale, streamline and simplify their business processing for maximum efficiency and productivity.

Contact our ERP experts, today!